Overview

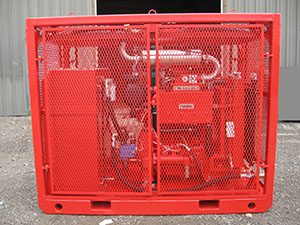

Custom built skid units built to your specifications. Units for slickline, logging, or combination work. Skid units built as 1 piece, 2 piece, and even 3 piece units with interchangeable drawworks sections. Units can be supplied meeting zone 2 requirements and designed and certified for use offshore to DNV 2.7-1. Units can be equipped with single drums, double drums, and options for split drums as well. Operators’ controls can be inside an enclosed cabin or in the open behind the drawworks. Enclosed cabins can be furnished with additional seating, logging systems, air conditioning, heater, and additional features to meet your requirements. One thing in common for all skid units is that they are designed and engineered to meet your requirements.